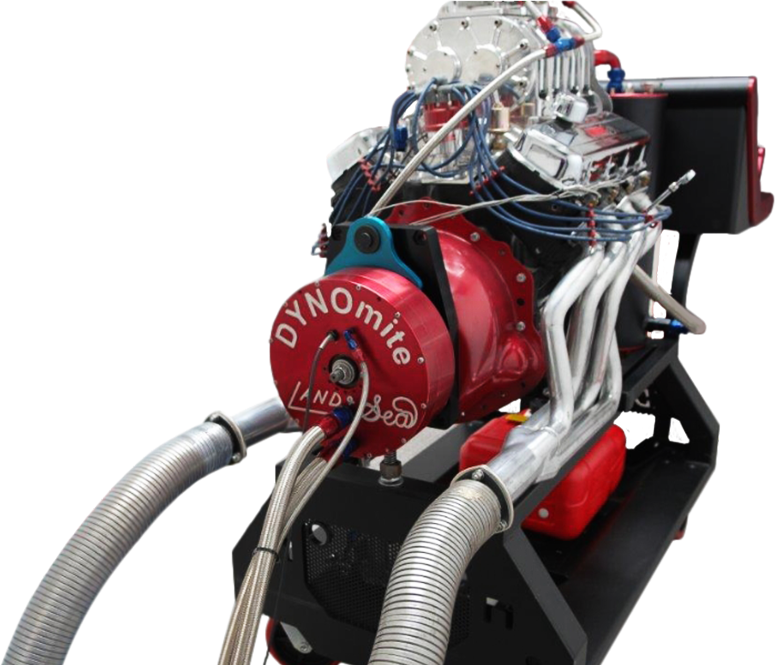

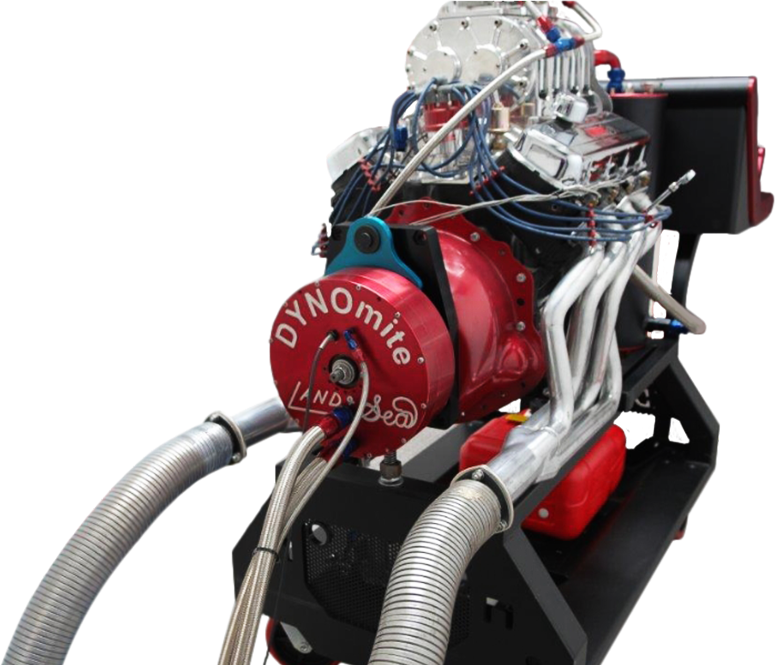

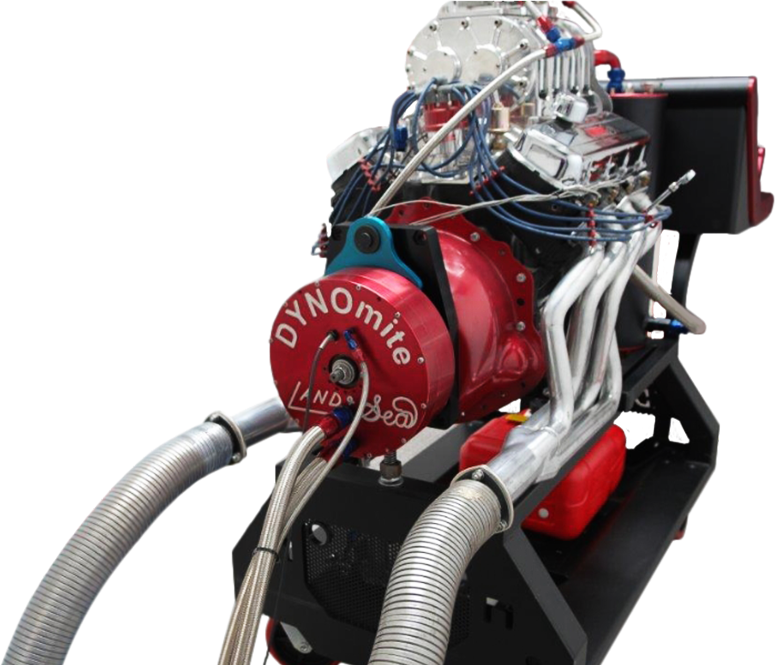

DYNOmite Water-Brake Absorbers are the first choice when low cost, low inertia, high rpm limits, and race engine horsepower capacity are all requirements. These have been the favorite of professional automotive engine builders for decades. Water brakes are similar to centrifugal water pumps. They typically have one or more vaned rotors spinning in between pocketed stator housings. Load is controlled by varying the volume of water recirculating within the brake with adjustable inlet and/or outlet valves and orifices. Raising this water level increases the rotational drag of the pump's rotor, applying more resistance to the engine turning it. Interestingly the water brake is, by design, a very inefficient pump. It uses up your engine's horsepower output by making "instant hot water"! Since the discharged hot water is clean, it can often be allowed to just run off, or air cooled and recirculated.

Power capacity versus size of water brakes is impressive. An 8 pound water brake can handles over 65 continuous Hp at 12,000 rpm! By comparison a 300 pound air-cooled eddy-current absorber with the same continuous power rating is only good to 7,000 rpm. It is no wonder that water brakes are virtually the only choice for testing 2,000+ horsepower drag car engines. Modern water brakes (like the one pictured at left) boast low enough weight and inertia that they can be directly mounted on the kart engine's output shaft. Direct mounting eliminates the inertia and parasitic drag of driveshafts, u-joints, pillow block bearing, etc.

DYNO

CHASSIS

DYNOJET

424xLC2

features

2 x 24"

The 424xLC2 features 2 x 24" knurled, precision balanced drums, 2x Eddy Current Load Absorption Units, measures up to 2000 HP, 2000 FT LBS, 200 MPH, and is capable of 1600HP peak absorption (in AWD) making it the most powerful load control dynamometer on the market.

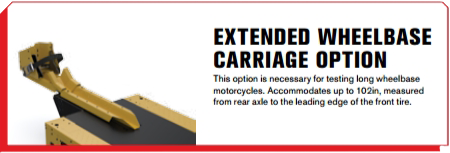

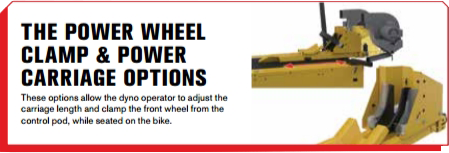

Unlike inferior non adjustable wheelbase designs, the model 424xLC2 can adjust wheelbase with a push of a button from 88” to 140”. This allows the tires to contact the rollers evenly and in conjunction with the large drum diameter the 424xLC2 provides a virtually flat, stable surface for tire contact eliminating unnecessary tire slippage and deformation. The result is precise, repeatable data every time.

The 424xLC2 can operate in “inertia only” mode for assessing gains from minor bolt-on modifications, or utilize the duel eddy currant load absorption units for advanced load testing. Load tests include step, sweep and custom road-load profiles in all gears and at any throttle position. This system also eliminates any potential speed bias between the two drums when using the Dynojet speed balance feature.

Horsepower and torque are measured at each drum and can be displayed and/or logged independently or combined. This feature allows you to assess the vehicle’s power-split and can also aid in troubleshooting drive-train issues.

With the addition of the optional Linx System, the 424xLC2 allows you to test modern AWD vehicles without the fear of potentially damaging the center differentials, or activating intrusive stability control systems. It is also useful for those 2wd performance vehicles that require all four wheels to be rotating in order to avoid "reduced power mode’’.

The 250i Load Control System was developed through years of experience with over 6,000 dynamometer installations world wide. The design is easy to operate and provide the function of steady state load control.

Dynojet's Load Control System uses the latest in Eddy Current Power Absorption technology, which combines with our easy to use software, so any technician can get repeatable, consistent results. The Load Control software provides the technician with the ability to control vehicle RPM or Speed at any throttle opening. Through our exclusive closed-loop software design, the vehicle is automatically held at your pre-determined setting.

\

\